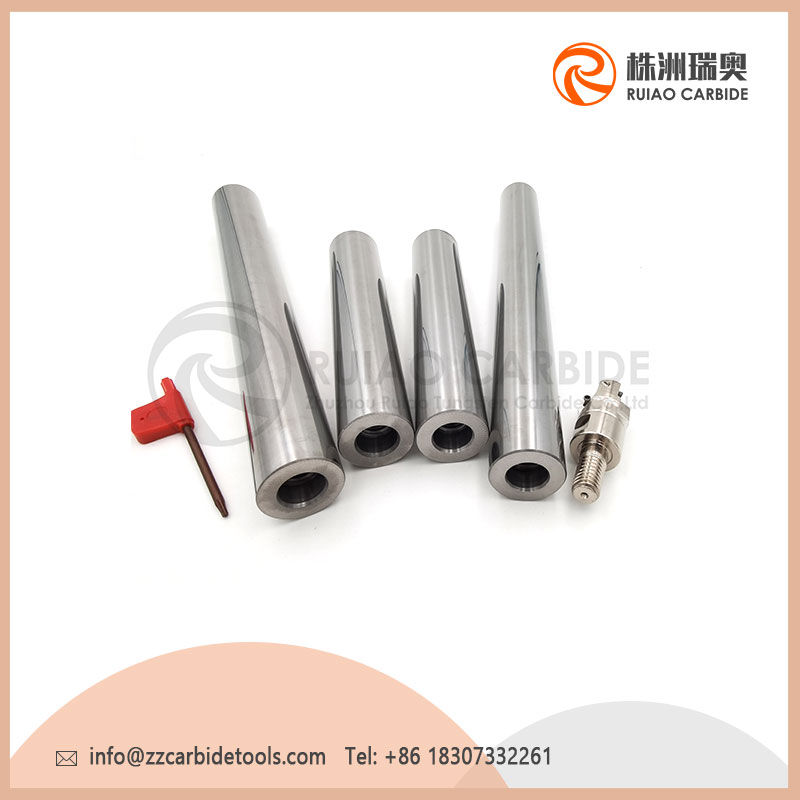

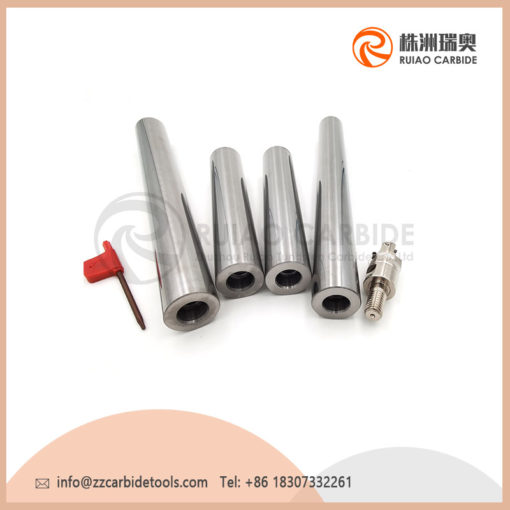

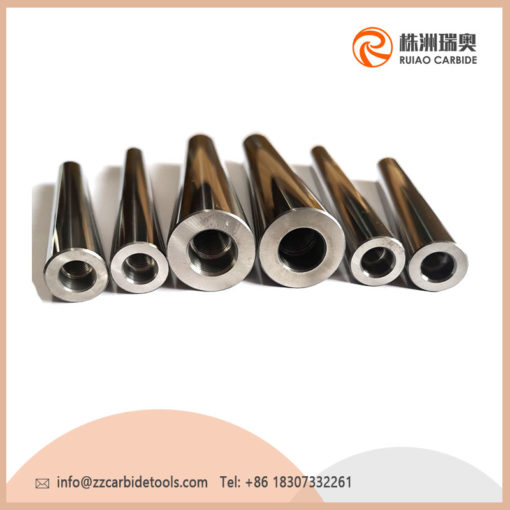

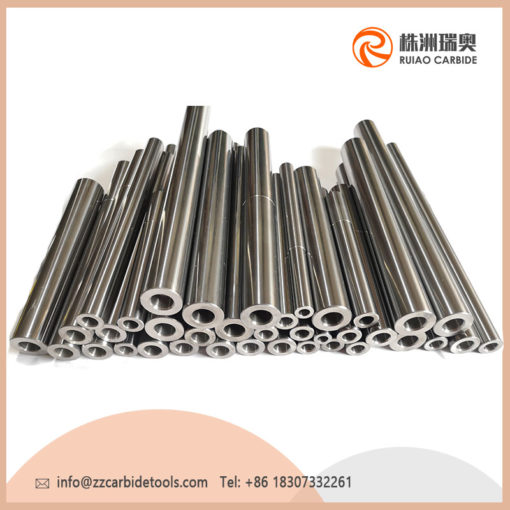

Extension Carbide Shank

Tungsten Carbide Extensions Shank with Screwed Thread

Advantage:

1.In stock for many standard size of semi-finished shank

2. Quality Guarantee

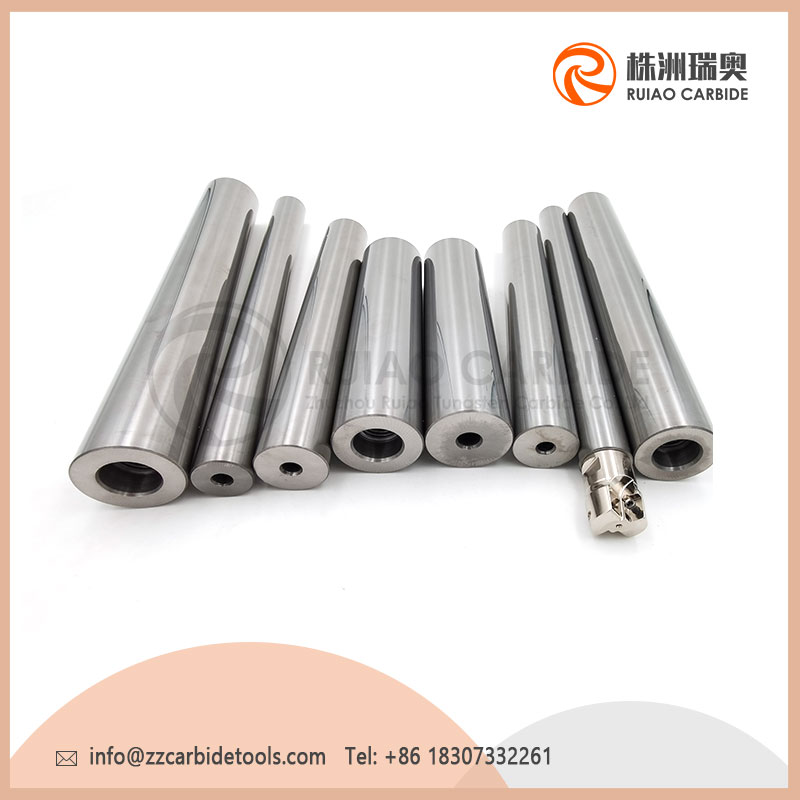

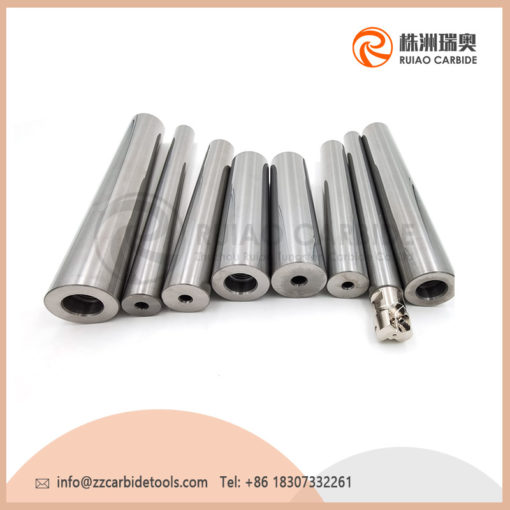

Anti Vibration Tungsten Carbide Shank/holder

Products Description

It is an important tool for for machining in CNC machining,Its purpose to prevent tools from shanking and to control,make tools vibarte which also called CNC extension rod. Especially as the CNC precision machining developing,the traditional CNC machining from 5000 rpm,6000 to 8000 rpm,after more sophisticated and efficient cutting speed will be developed to more than 20,000 turn. Such high-speed cutting, Higher requirements of sufficient seismic performances is needed carbide stamping pole must be uniform material, consistent performance of its and Precision concentric assurance to achieve such a high speed cutting operation requirements.

Extension Tungsten carbide shank, the thread locking teeth seismic tool bar through the hollow design, all tungsten carbide material, threaded connection tool head and other ways to achieve seismic effect.

The specific analysis is as follows:

Hollow design: most of the seismic tool bar is hollow, can minimize the vibration generated during processing, such seismic tool bar is suitable for machining center high-precision processing, but also can be used in high-speed engraving, high-speed milling.

Full tungsten carbide material: made of full tungsten carbide material, rigidity, toughness, excellent wear resistance, good shock absorption, will not be due to excessive transverse force, and distortion, 8 times higher than ordinary steel shock resistance.

Threaded tool head: The tool head and tool rod are threaded and run in reverse with the direction of the main shaft.

Feature

1. Super hard tungsten carbide boring bar made of high toughness compound, tough and durable.

High physical and chemical characteristics of superhardness. High rigidity and additional vibration resistance, ideal for extra depth boring (10D)

2. Standard internal coolant holes are built in each size bar for best cooling and chip removal in deep hole boring.

3. With a straight handle structure, the rod can be adjusted to different working lengths.

4. At both ends of the main body are welding holes. One hole will be replaced by another on a breakthrough. This will reduce your costs and greatly increase the value of the boring bar.

5. Both ends of the body are combined with the hole, and in the case of damage at one end, the other side can be used together to increase the value of the tool bar itself, which is more in line with economic benefits.

6. The internal thread of the tool rod and the tungsten steel tool rod are sintered at one time, the thread is more stable and durable, and it is not easy to collapse without electrical damage.

Related products

Tungsten Carbide Shank