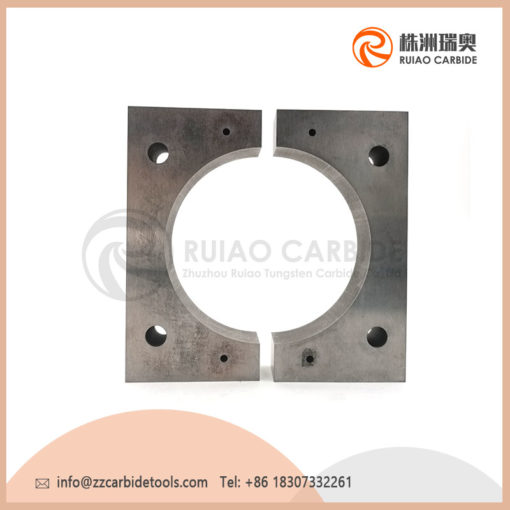

Tungsten Carbide Flow Control Cag

Tungsten carbide grinding bowls and mortar is the highest density grinding tools for laboratory grinding mill, ball mill machine, power grinder,ball mill crusher etc.High hardness and strengthness can meet the application of crushing and refining for most majority of metal powder, especially those hard and super hard metal powder.

Carbide Flow Cage is a fluid control component designed for harsh industrial environments, combining material properties with structural design. A detailed breakdown is as follows:

1. Material Properties: Carbide

- High Hardness & Wear Resistance: Typically refers to tungsten carbide (WC) or similar hard alloys, offering exceptional hardness and wear resistance, ideal for abrasive environments (e.g., particle-laden fluids).

- Corrosion Resistance: Performs well in corrosive media (e.g., acidic or alkaline fluids), commonly used in chemical or petroleum industries.

- High Temperature & Pressure Resistance: Suitable for extreme temperature and pressure conditions, such as drilling or high-pressure fluid syste

Super wear-resistant, double life

1.The material is made of high purity tungsten-cobalt carbide (YG8/YG11), the hardness is ≥HRA89, the wear resistance is 5-8 times that of ordinary steel nozzles, and can withstand cuttings erosion and acid corrosion.

The surface is treated with nano coating to further reduce the friction coefficient and extend the stable working cycle.

2. Precision fluid design improves rock breaking efficiency

Multiple models can be selected (such as cone, straight hole, rotary flow), injection Angle of 15°-30° can be accurately adjusted, forming high-speed focused jet (flow rate of 150-200m/s), effectively removing rock debris at the bottom of the hole, reducing the risk of drill “mud”.

Flow coefficient (Cv value) optimization design, matching different drilling fluid viscosity, to ensure efficient conversion of hydraulic energy into rock breaking power.

3. High temperature and pressure resistance, suitable for extreme working conditions

Operating temperature range: -50℃ to 400℃, pressure strength ≥80MPa, to meet the ultra-deep well (8000 meters +) and shale gas horizontal well operation requirements.

Threaded interface adopts API standard (such as 1-1/2 “REG, 2-3/8” IF), sealing grade PPL, prevent leakage.

4. Modular design for quick replacement

Standardized threaded connection structure (such as NPT, BSPT), suitable for mainstream tricone bit, PDC bit and screw drill, support downhole instant replacement, reduce downtime.

Technical parameter

Parameter Specifications

Material YG8/YG11 carbide (optional tungsten carbide enhanced)

The working pressure is 35MPa for conventional type and 80MPa for enhanced type

Diameter range Φ6mm-Φ20mm (±0.02mm tolerance)

Connection thread API standard, NPT, BSPT and other customized interfaces

Applicable bit types: tricone bit, PDC bit, diamond bit

Application scenario

Deep oil and gas reservoir development: dealing with granite, flint and other highly abrasive formation

Shale gas horizontal Wells: Efficient guided injection with hydraulic fracturing technology

Geothermal well drilling: high temperature design to ensure the stability of geothermal resources development

Mining exploration bits: Reduce frequent replacement costs in hard rock drilling

With the core value of reducing the drilling cost per meter by 15% and increasing the bit life by 30%, the product has become a long-term partner of CNPC, Schlumberger and other companies, and has served 3,000 + oil and gas Wells worldwide with a failure rate of less than 0.5%.

Production show

Related products

Perform Tungsten Carbide

Perform Tungsten Carbide

Perform Tungsten Carbide