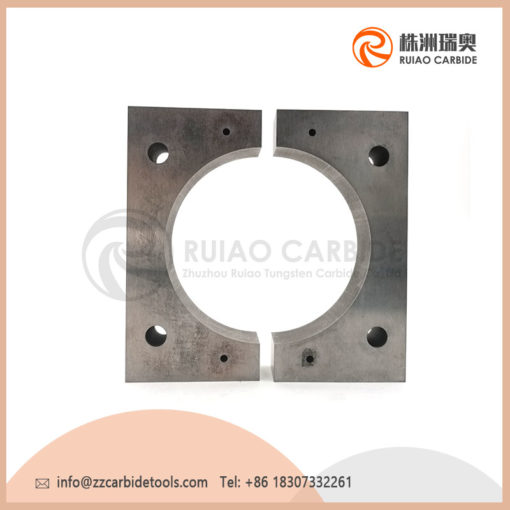

Tungsten Carbide Grinding Pegs

Solid Tungsten carbide rod is mainly applied in making drills, end mills,screw tap and reamers. And it is also used for cutting, punching and measuring tools. It is used in the industries of paper making, package, printing, non-ferrous metal processing. Also, it’s an excellent material to processe as HSS cutting tool and holemaking tools,wear-resistant parts,shanks for drill bits and etc.

Products Description

Tungsten carbide pegs is an important part of rod pin nano sand mill, carbide pin with high wear resistance, high hardness, high strength, not easy to break, easy installation and maintenance, no metal pollution known, good heat dissipation performance, rod pin length and grinding cylinder diameter ratio design Reasonable, high grinding efficiency; Suitable for dispersion grinding of digital printing ink, solvent ink, water-based ink, automotive paint, industrial paint, pigment, color paste, and nanomaterials.

Standard size range (customized welcome)

| OD (mm) | L(mm) | M (mm) |

|---|---|---|

| ø12mm | 33-35mm | M8 |

| ø10mm | 35-48mm | M10 |

| ø14mm | 30-58mm | M12 |

| ø16mm | 48-60mm | M12 |

| ø20mm | 60-73mm | M16 |

| ø30mm | 108-131mm | M20 |

Performance advantage

- Material: integral tungsten carbide, welded type (SUS304SUS316+ Tungsten carbide alloy), SUS304 ensures no rust and high toughness; The welding agent is divided into brazing and silver welding.

- Grade: Depending on whether the grinding material is water-based or oily, YG and YN medium/ultrafine particles are recommended, which can be customized.

- Appearance: mirror-polished R0.4, hexagon/chamfer/withdrawal slot/wrench position/positioning hole/top round head/top flat head with drawings.

- Thread :CNC machining, good thread concentricity, since M4, standard pitch/coarse/fine teeth, easy to install; There are no welds, missing welds or falling off at the joints.

- Quality inspection: product quality inspection specifications, according to the standard torque test; The weight of the finished product is consistent, and the motor runs more stable.

Core Technology Advantages

-

Triple-High Performance

-

Wear Resistance: 20× longer lifespan vs. ceramic pegs in nano-grinding

-

Hardness: HRA 91.5±0.3 (ISO 3878)

-

Transverse Rupture Strength: ≥4,500 MPa (eliminates fracture risks)

-

-

Zero-Contamination Guarantee

-

Material Purity: WC 99.95% + Co/Ni binder (O₂ ≤ 0.1%)

-

Certified non-metallic pollution per ISO 10993-18

-

-

Thermal Management System

-

Thermal conductivity: 85 W/m·K (3× faster than steel)

-

Operational stability: -50°C to 400°C

-

-

Optimized Geometry

-

Pin Length : Grinding Cylinder Diameter = 1:1.2~1.5 (patented ratio)

-

Surface roughness: Ra ≤0.05μm (mirror-polished)

-

Technical Specifications

| Parameter | Standard Range | Customization |

|---|---|---|

| Diameter | Ø0.8mm – Ø15mm | ±0.002mm tolerance |

| Length | 5mm – 150mm | Laser marking |

| Straightness | ≤0.003mm/100mm | Tapered designs |

| Binder System | WC-6%Co (Standard) | WC-8%Ni (Corrosion) |

| Coating | Uncoated (Standard) | Diamond coating |

Nano-Grinding Applications

Digital Printing Inks

-

Solvent-based: CMYK process colors, white ink dispersion ≤100nm

-

Water-based: Pigment concentration ≥40%, D50 <150nm

Advanced Coatings

-

Automotive: Metallic effect paints, UV-cured primers

-

Industrial: Anti-corrosion coatings, ceramic suspensions

Nanomaterials

-

Graphene dispersions (≤5 layer thickness)

-

Quantum dot solutions (PDI <0.2)

-

TiO₂/ZrO₂ suspensions (D90 <200nm)

Installation & Maintenance Features

-

Plug-and-Play Design:

-

Precisely fitted mounting slots (±0.01mm)

-

Quick-change system (replace single peg in ≤5 min)

-

-

Failure Prevention:

-

Chamfered edges prevent cylinder scoring

-

Stress-relieved microstructure (per ASTM B406)

-

Related products

Perform Tungsten Carbide

Perform Tungsten Carbide

Perform Tungsten Carbide