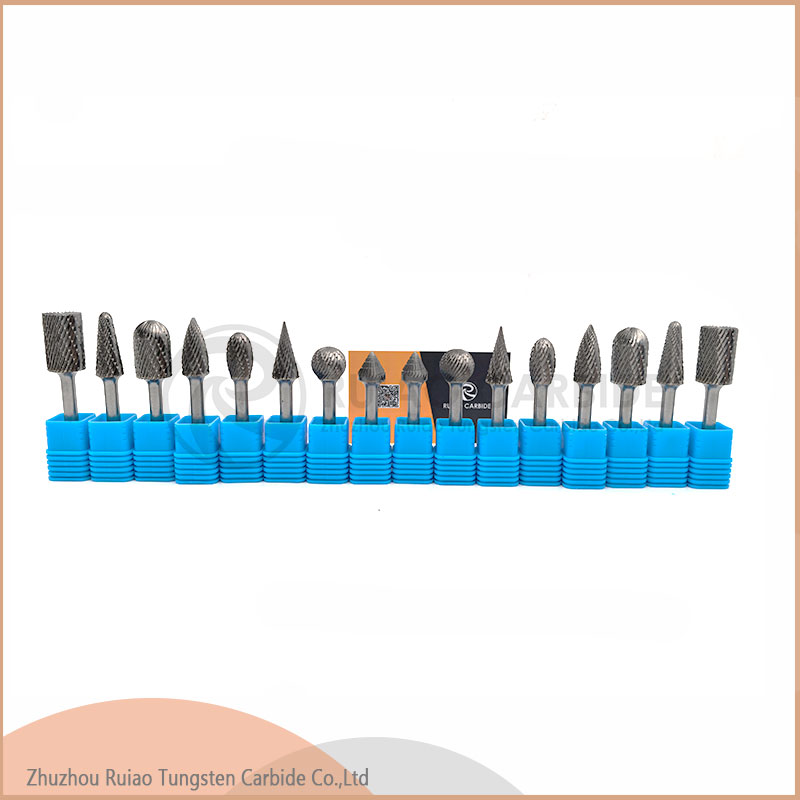

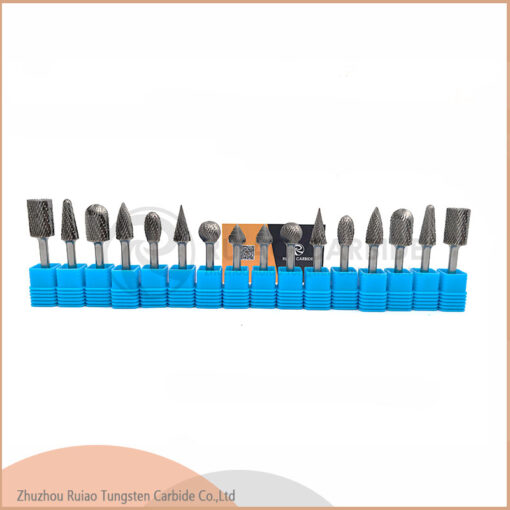

Tungsten carbide rotary burrs

Carbide Rotary Files/Tungsten Carbide Burrs

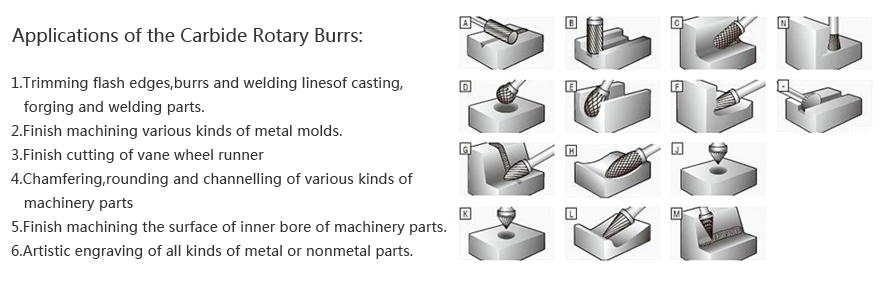

1, Used for finishing the surfaces of metal and non-metal

2, Removing the burrs of casting, forging and the welding spatter on the weld assemblies

3, Chamfering angle, circular bead or flute on the mechanical parts

4, Chamfering or burring the pipes.

5, Polishing the impeller channel

6, Grinding the hole for accurate shape