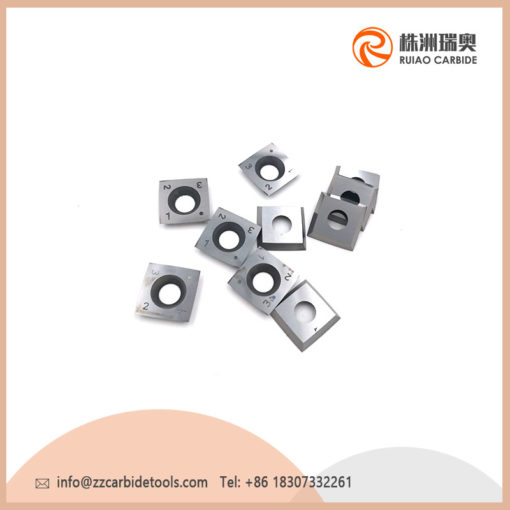

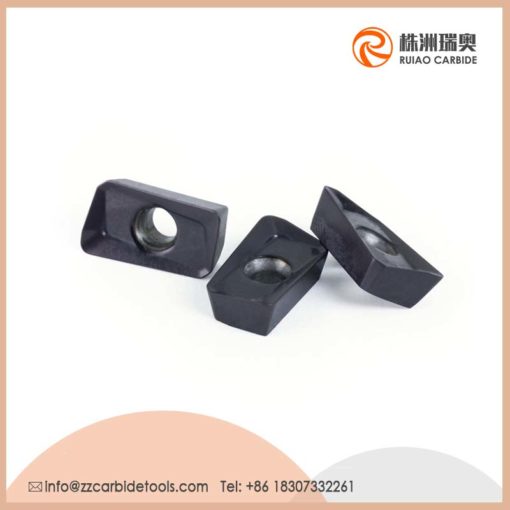

Tungsten Carbide Turning Insert

1. Dimension accurate, durable and reliable performance.

2. High quality with competitive price.

3. Widely used in industry of metalworking machinery

4.Long service life and high wear resistance.

5.Excellent edge strength.

Category: Tungsten Carbide Cutting Tools

CNC Tool Insert Material Introduce

1) Coated Carbide(CVD)

Applicable from low to high speed cutting and from finishing to rough machining.

Stable cutting is achieved due to the superior toughness and crack resistance.

Cutting times are reduced due to good chip control from effective chipbreakers.

Achieving superior processing efficiency in the field of a wide range of steel/casting Parts processing.

2) Coated Carbide(PVD)

Good for low to high speeds and finishing to heavy roughing cutting.

Stable cutting with excellent toughness.

Smooth fine surface of PVD coated carbide provides good surface finish and high.

Achieved high reliability in the unstable processing field of stainless steel

3) Cermet

Excellent wear resistance enables high cutting speeds

Cermet maintains good surface finished due to the low affinity to workpiece material.

Excellent wear resistance enables high cutting speeds.

4) Carbide

Tough and Hard, good thermal conductivity

Suitable for cutting non-ferrous metals and non-metals

Stable cutting at low cutting speeds, including milling operations

5)CBN

Superior wear resistance when cutting hard materials

Suitable for high speed cutting of cast iron and sintered steel

High thermal conductivity provide stable cutting

Applicable from low to high speed cutting and from finishing to rough machining.

Stable cutting is achieved due to the superior toughness and crack resistance.

Cutting times are reduced due to good chip control from effective chipbreakers.

Achieving superior processing efficiency in the field of a wide range of steel/casting Parts processing.

2) Coated Carbide(PVD)

Good for low to high speeds and finishing to heavy roughing cutting.

Stable cutting with excellent toughness.

Smooth fine surface of PVD coated carbide provides good surface finish and high.

Achieved high reliability in the unstable processing field of stainless steel

3) Cermet

Excellent wear resistance enables high cutting speeds

Cermet maintains good surface finished due to the low affinity to workpiece material.

Excellent wear resistance enables high cutting speeds.

4) Carbide

Tough and Hard, good thermal conductivity

Suitable for cutting non-ferrous metals and non-metals

Stable cutting at low cutting speeds, including milling operations

5)CBN

Superior wear resistance when cutting hard materials

Suitable for high speed cutting of cast iron and sintered steel

High thermal conductivity provide stable cutting

6) PCD (Diamond Sinter)

Applicable for non-ferrous metals, non-metals turning milling and other various type of cutting .

Reduced edge build-up allows for high precision cutting.

Diversified applications for cutting of non-ferrous metals and non-metals.

Finished surface will be rainbow colored.(a mirror-like finished surface will not be obtained when single crystal diamond is used.)

Applicable for non-ferrous metals, non-metals turning milling and other various type of cutting .

Reduced edge build-up allows for high precision cutting.

Diversified applications for cutting of non-ferrous metals and non-metals.

Finished surface will be rainbow colored.(a mirror-like finished surface will not be obtained when single crystal diamond is used.)

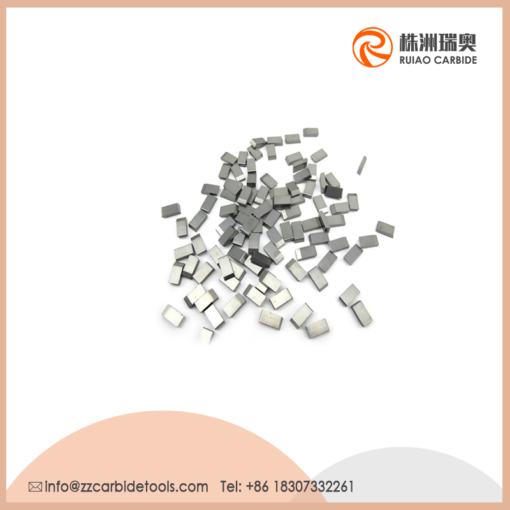

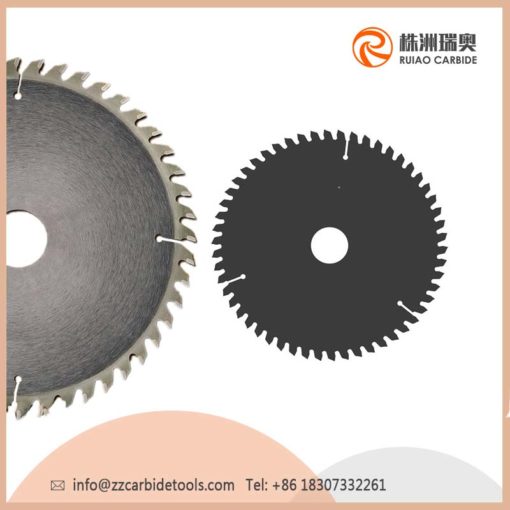

Related products

Tungsten Carbide Cutting Tools

Tungsten Carbide Cutting Tools

Tungsten Carbide Cutting Tools

Tungsten Carbide Cutting Tools

Tungsten carbide turning insert/PCD/PCBN cutting tools/CNC inserts

Tungsten Carbide Cutting Tools