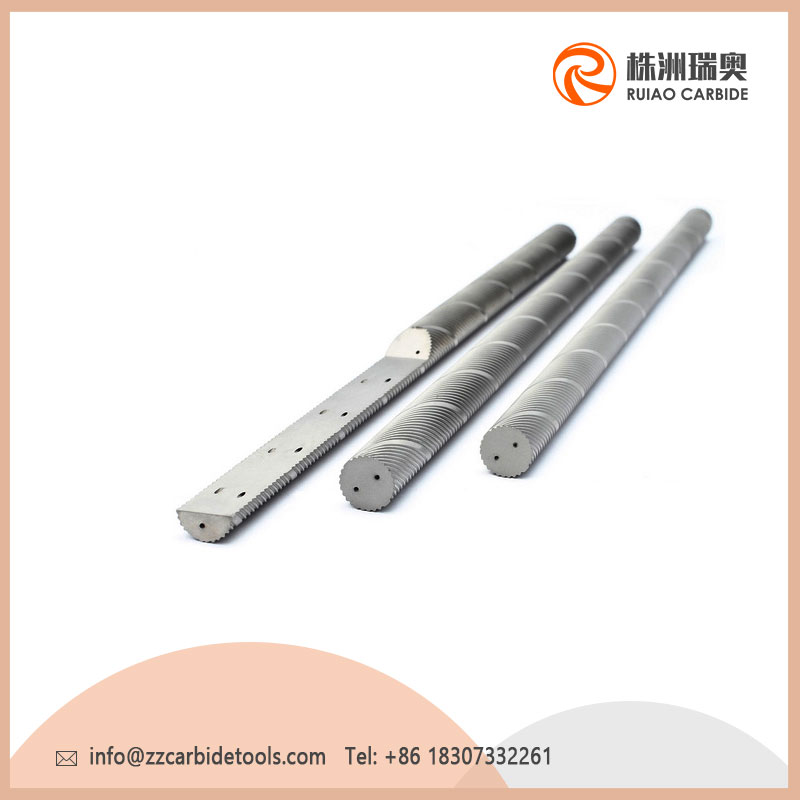

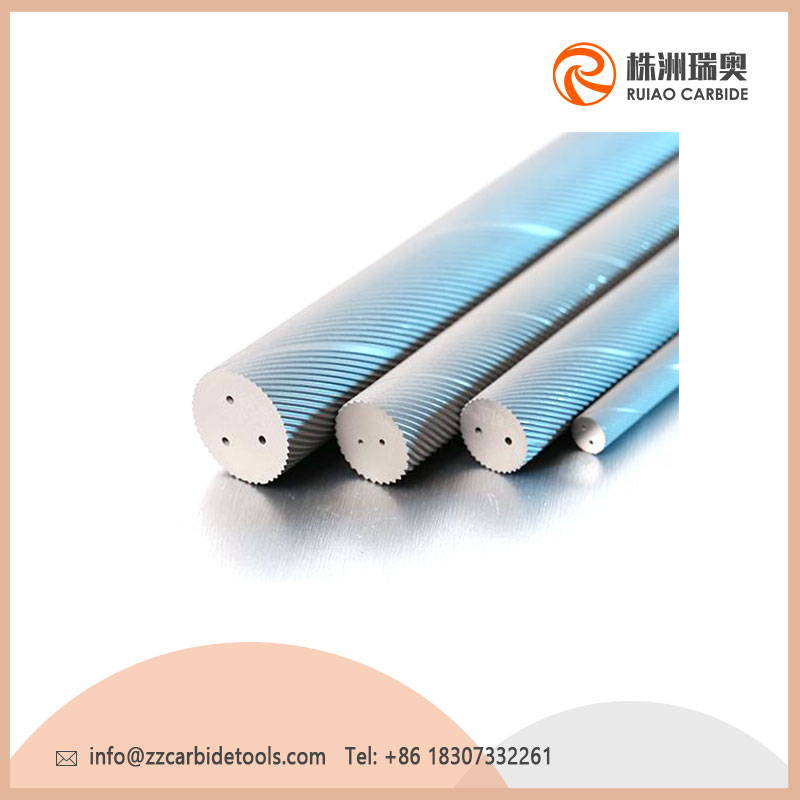

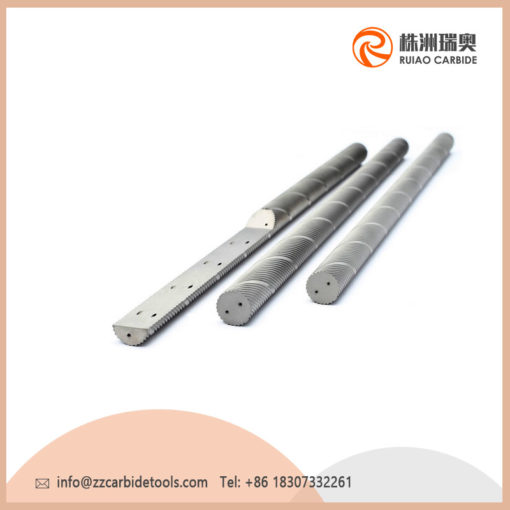

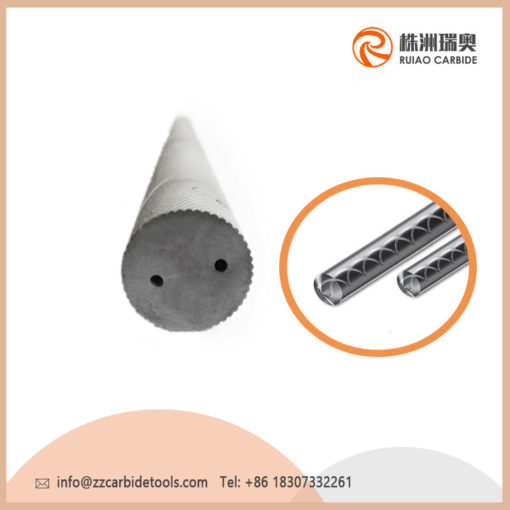

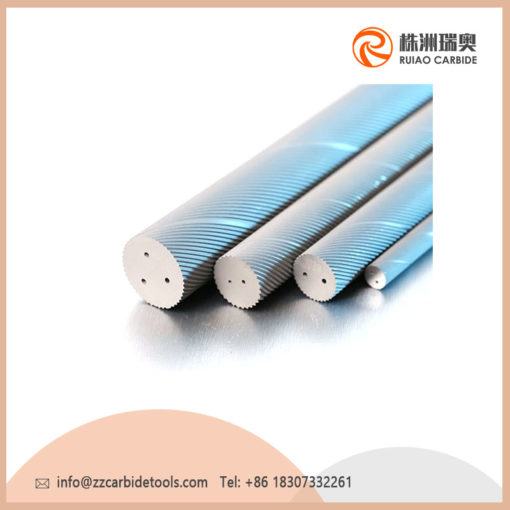

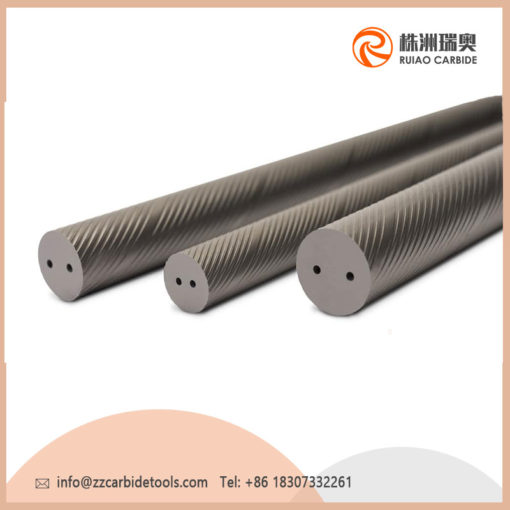

Carbide Rod With Helical Coolant Holes

Carbide rods with helical coolant holes are widely applied for drill bits, end mills, and reamers.

Precision Engineered for Extreme Performance

Product Description

Our cemented carbide (tungsten carbide) round bars are manufactured through advanced sintering technology, delivering exceptional hardness, wear resistance, and structural stability. Ideal for high-stress applications in machining, wear parts, and industrial tooling.

Key Features:

-

Ultra-High Hardness: HRA 90+ (Rockwell Scale)

-

Superior Wear Resistance: 6–8× longer service life vs. HSS

-

Corrosion Resilience: Resists acids/alkalis (excl. strong oxidizers)

-

Thermal Stability: Maintains integrity up to 900°C

-

Precision Tolerance: Diameter ±0.01mm (customizable)

Typical Applications:

✓ Cutting tool blanks

✓ Wear-resistant guide rods

✓ Punch & die components

✓ Deep drawing mandrels

✓ Precision measuring instruments

Customization Support:

・Tailored dimensions & tolerances

・Special surface treatments (TiN, DLC coating)

・Non-standard alloy formulations

Tungsten Carbide Rods With Tolerance H6, h6, H5, h5, H7, h7

|

Grade |

Density g/cm³ | Hardness (HRA) | T.R.S (Mpa) | Grain Size(μm) | Composition(%) | Equal to ISO |

|

RA06 |

14.8 | ≥94 | ≥3500 | 0.4 | 6% CO 93.5% WC | K05/K10 |

|

RA08 |

14.5 | ≥93 | ≥3500 | 0.4 | 8.5% CO 91% WC | K10/K20 |

|

RA09 |

14.44 | ≥93 | ≥4100 | 0.2 | 9% CO 90.5% WC |

K10/K20 |

| RA10 | 14.5 | ≥91.8 | ≥3800 | 0.6 | 10% CO 89.5% WC |

K20/K30 |

| RA11 | 14.5 | ≥91.8 | ≥3500 | 0.8 | 10% CO 89.5% WC |

K20/K30 |

| RA12 | 14.2 | ≥92.8 | ≥4000 | 0.5 | 12% CO 87.5% WC |

K20/K30 |

The Specification Range of extruded Grounded Tungsten Carbide Rod :

WC Grain size range: 0.3~0.5μ.m; 0.5~0.9μ.m; 1.0~1.3μ.m; 1.4~2.0μ.m.

Length range:3mm-600mm; (General Length: 100mm,300mm,320mm,330mm)

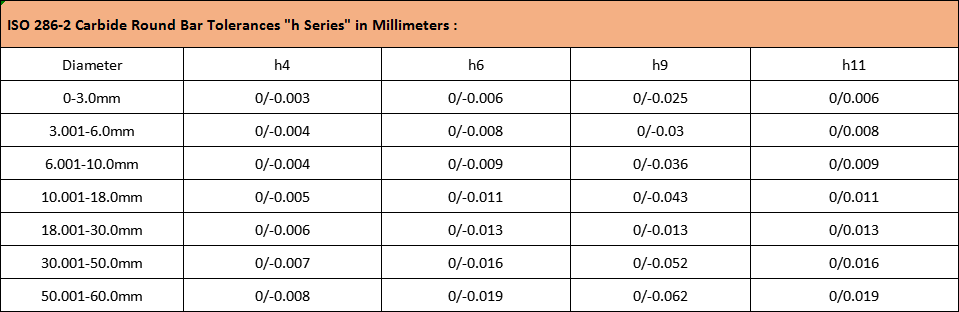

Diameter Grade: h4(H4), h5(H5), h6(H6), h7(H7), h8(H8), h9(H9), etc.

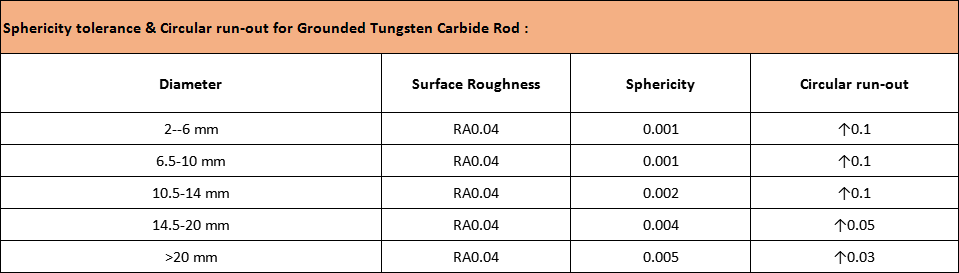

Good grinding machine to ensure the sphencity & the Linearity of rod at higher level standard;

Sphericity tolerance range: 0.001mm ~ 0.005mm;

Linearity tolerance range: 0.001mm~0.1mm;

Surface Roughness can be reached to: Ground/Polished (Ra≤0.2μm).(reach a mirror effect surface after fine grinding)

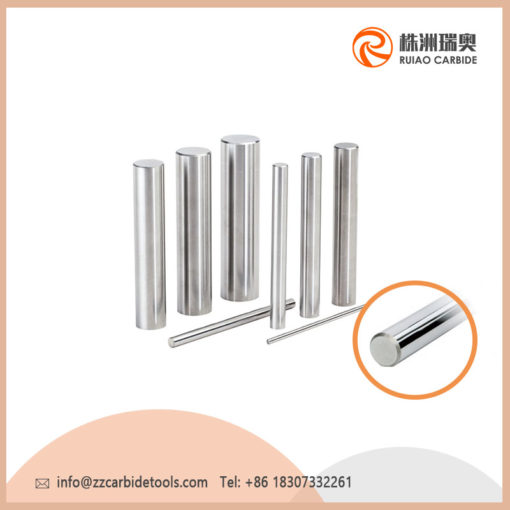

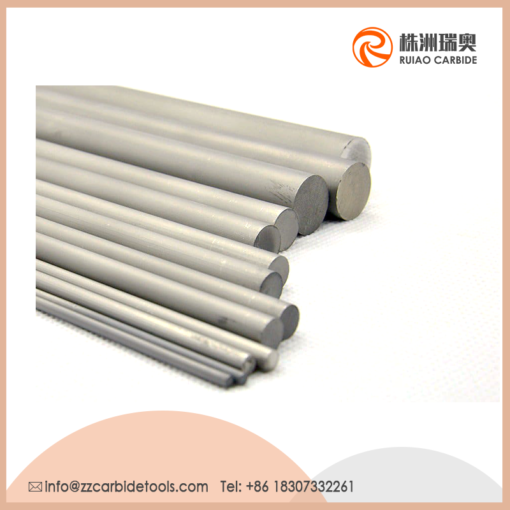

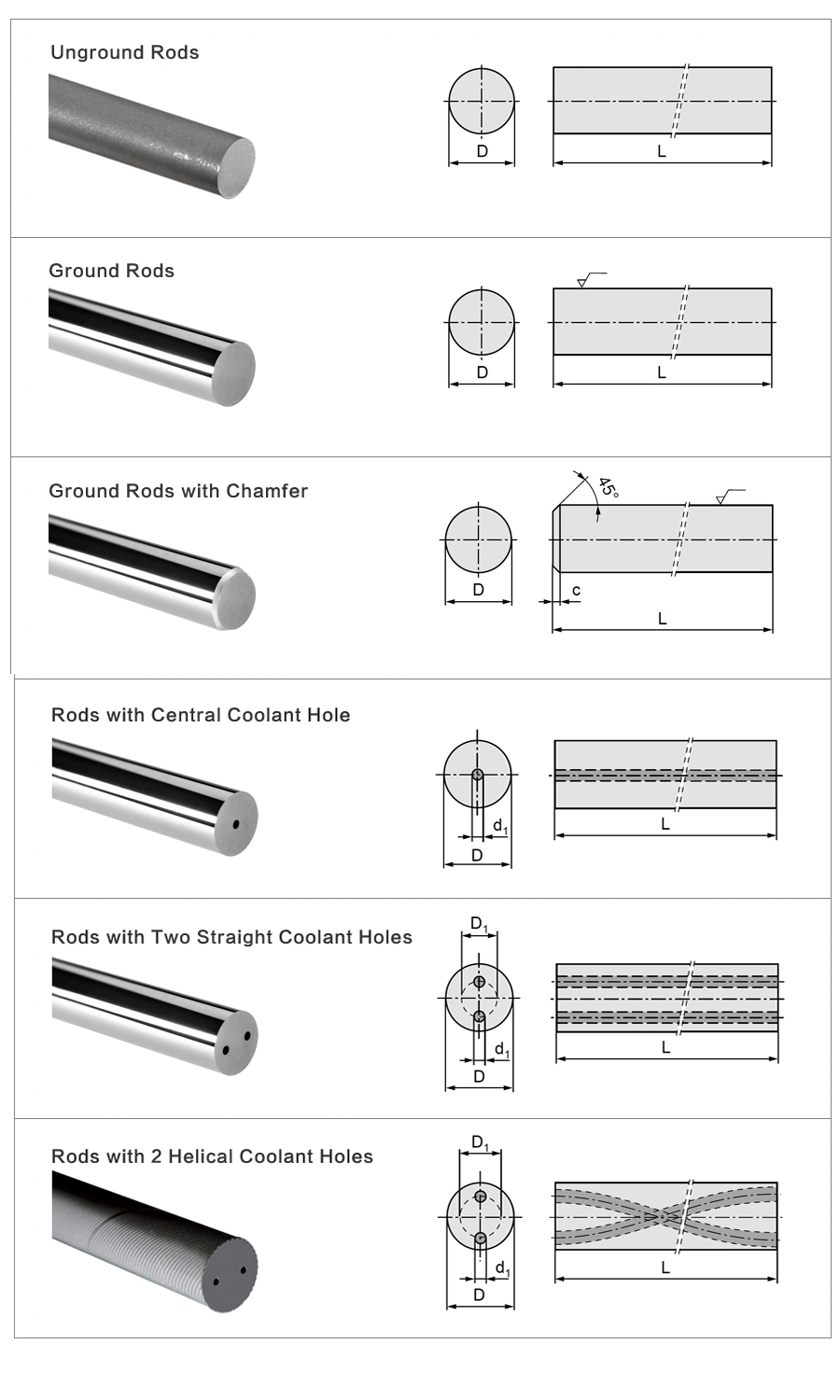

Related products

Tungsten Carbide Rods

Tungsten Carbide Rods

Tungsten Carbide Rods

Tungsten Carbide Rods

Tungsten Carbide Rods