Application:

The tungsten carbide punch pin is made of carbide round rod fine grinding, with high precision, high hardness and good bending strength.

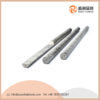

The Specification Range of extruded Grounded Tungsten Carbide Rod :

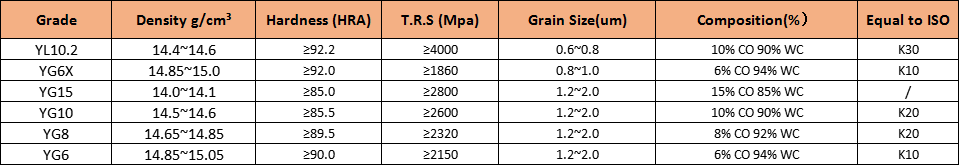

WC Grain size range: 0.3~0.5μ.m; 0.5~0.9μ.m; 1.0~1.3μ.m; 1.4~2.0μ.m.

Length range:3mm-600mm; (General Length: 100mm,300mm,320mm,330mm)

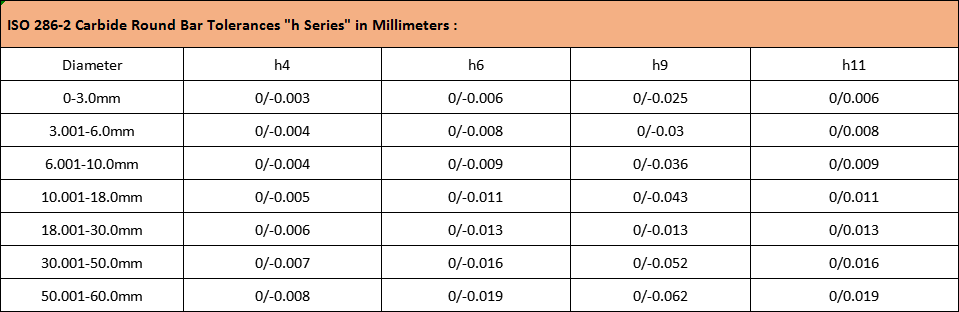

Diameter Grade: h4(H4), h5(H5), h6(H6), h7(H7), h8(H8), h9(H9), etc.

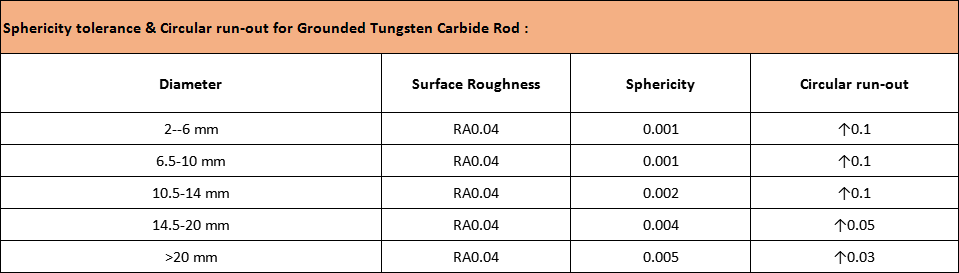

Good grinding machine to ensure the sphencity & the Linearity of rod at higher level standard;

Sphericity tolerance range: 0.001mm ~ 0.005mm;

Linearity tolerance range: 0.001mm~0.1mm;

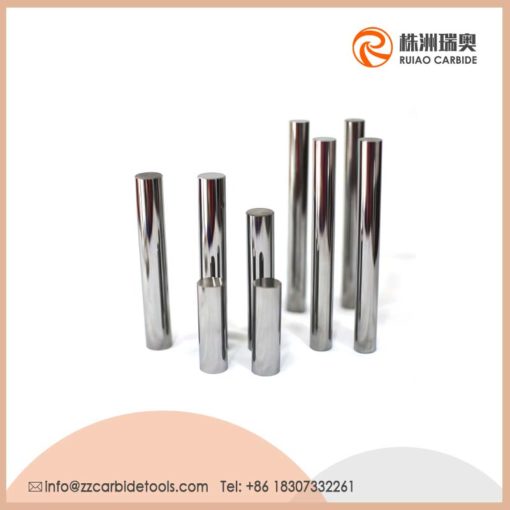

Surface Roughness can be reached to: RA0.04.(reach a mirror effect surface after fine grinding)

Production technology

Ingredients (Main ingredients :WC+TiC+TaC+Co+VC+……) → Full mixing → crushing → Drying → Adding molding agent after sifting → drying → sifting mixture → Mixing granulation and pressing → molding → low pressure sintering → Blank after sintering → Inspection (non-destructive ultrasonic inspection)→ blank dimensional accuracy inspection → Electric discharge machining (or wire cutting molding)→ rough grinding → fine grinding → polishing → Inspection → Marking → Packaging.

Product use

Its application field is very wide, because it has the characteristics of acid and alkali resistance, no rust and long service life, the pharmaceutical industry selected its punch for the production of stamped tablets.

Related products

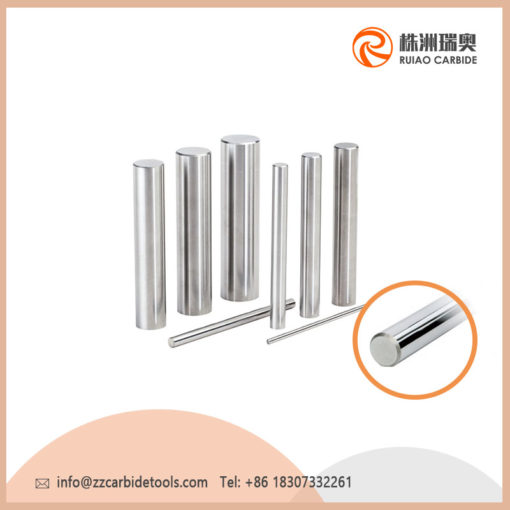

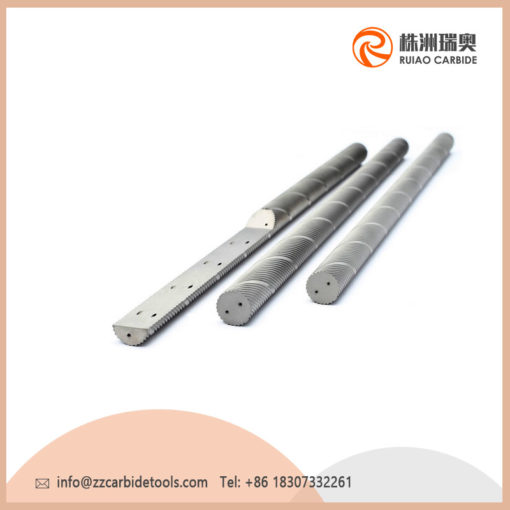

Tungsten Carbide Rods

Tungsten Carbide Rods

Tungsten Carbide Rods

Tungsten Carbide Rods

Tungsten Carbide Rods