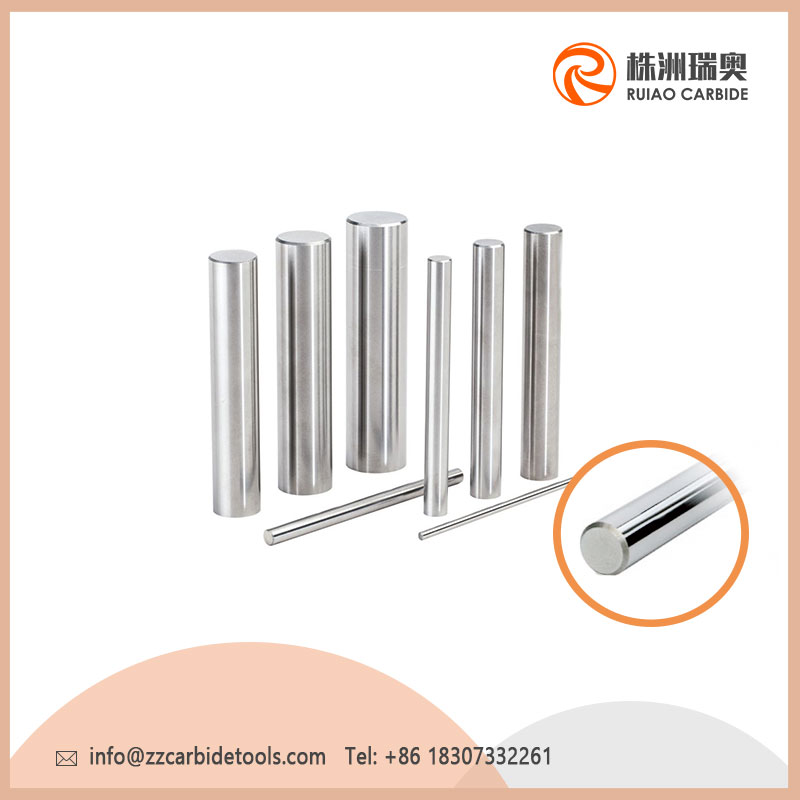

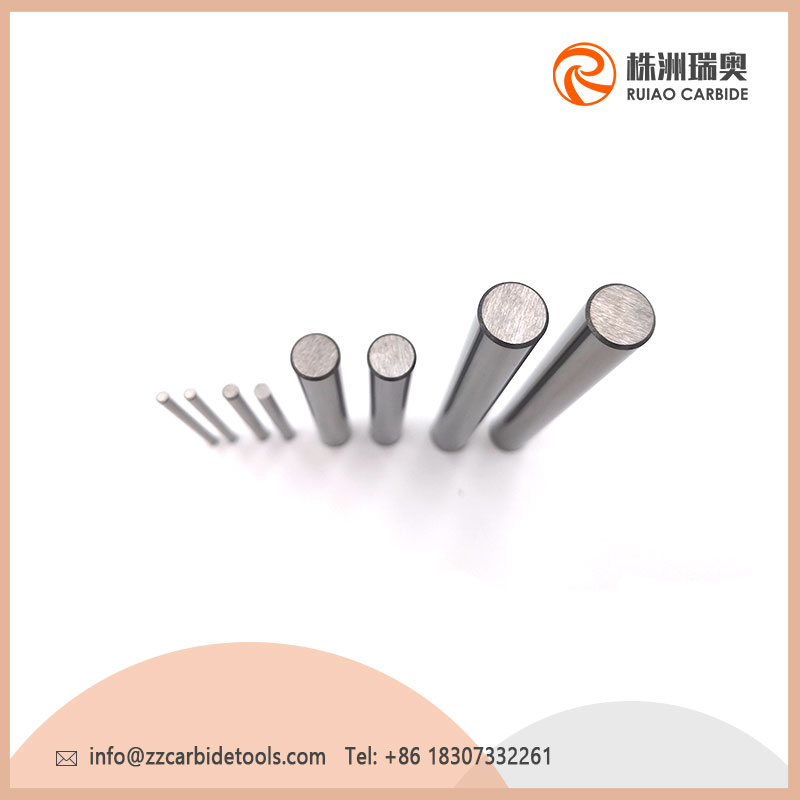

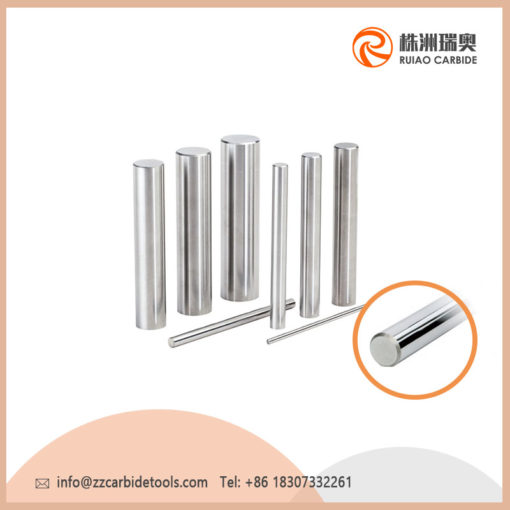

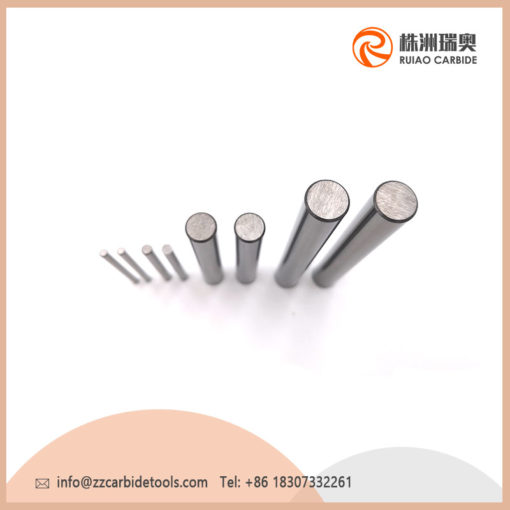

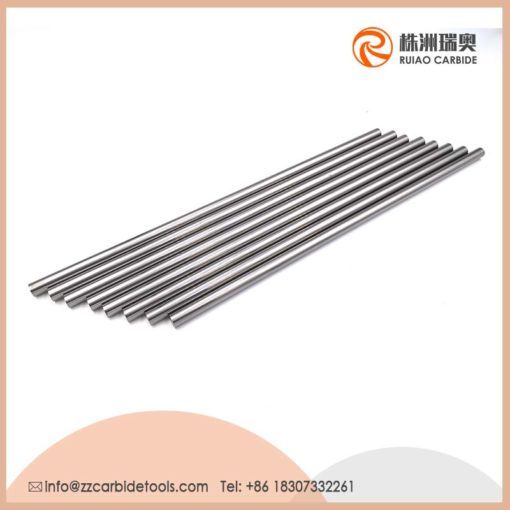

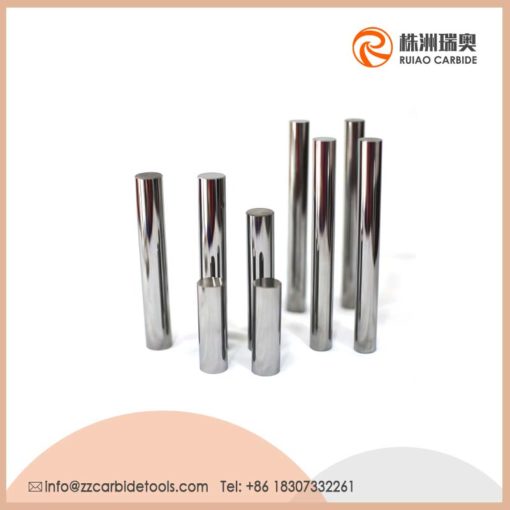

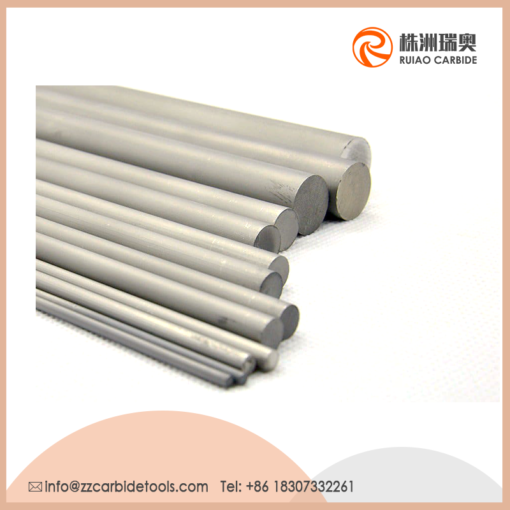

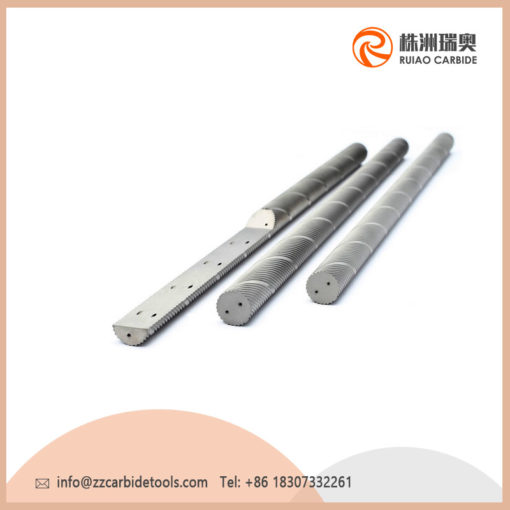

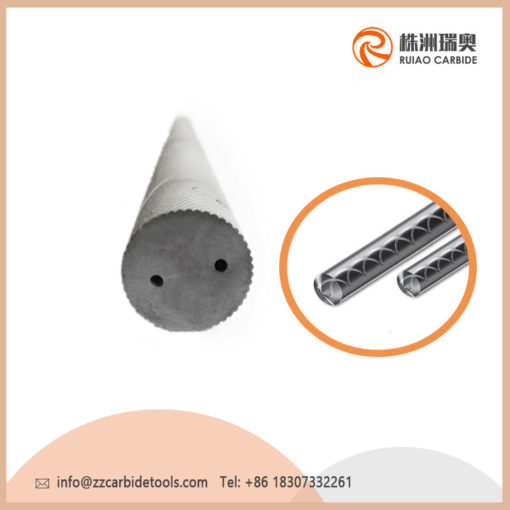

Carbide Rods With Chamfer For MDF

Carbide rods are mainly used in drill bits, end milling cutters, winch. It can also be used for cutting, stamping and measuring tools. It is used in papermaking, packaging, printing, non-ferrous metal processing. In addition. It is also widely used in machining high speed steel cutting tools, carbide milling cutters, NAS cutting tools, aviation cutting tools, cemented carbide bits, milling cutter cored bits, high speed steel taperd milling cutters. Metric milling cutters, miniature end milling cutters, hinge pilot, electronic tools, step drills, metal cutting saws, double margin drills, guns, angle milling cutters, carbide burrs, carbide cutters, etc.

Min BL-Φ3.0×330, Max BL-Φ50.0×330